Ngokukhula kwesidingo sokuqapha ukulayishwa kwemigwaqo namabhuloho ekuphathweni kwethrafikhi yesimanje, ubuchwepheshe be-Weigh-In-Motion (WIM) buye baba ithuluzi elibalulekile lokulawulwa kwethrafikhi nokuvikela ingqalasizinda. Imikhiqizo yezinzwa ze-quartz ye-Enviko, ngokusebenza kwayo okuhle kakhulu nokwethembeka, isetshenziswe kabanzi ezinhlelweni ze-WIM.

Izimiso ze-Quartz Weigh-In-Motion (WIM) Algorithms

Umongo wesistimu ye-quartz Weigh-In-Motion (WIM) ukukala ingcindezi ekhishwa endaweni yomgwaqo ngezimoto ngesikhathi sangempela zisebenzisa izinzwa ze-quartz ezifakwe emgwaqeni. Izinzwa ze-quartz zisebenzisa umphumela we-piezoelectric ukuguqula amasignali okucindezela abe amasignali kagesi. Lezi zimpawu zikagesi ziyakhuliswa, ziyahlungwa, futhi zifakwe kwidijithali, ekugcineni zisetshenziselwa ukubala isisindo semoto.

Izinzwa ze-quartz ze-Enviko ezisetshenziswa ezinhlelweni ze-WIM zinokuzwela okuphezulu nezici zokuphendula imvamisa ebanzi, okuzivumela ukuthi zithwebule ngokunembile izinguquko zengcindezi esheshayo njengoba izimoto zidlula phezu kwazo. Ukwengeza, izinzwa ze-quartz zinokuzinza okuhle kakhulu kwezinga lokushisa nokuphila isikhathi eside, zigcina ukusebenza okuzinzile ezindaweni ezihlukahlukene ezinokhahlo.

Izinyathelo ze-Weigh-In-Motion (WIM) Algorithm

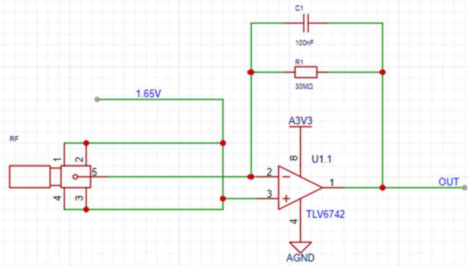

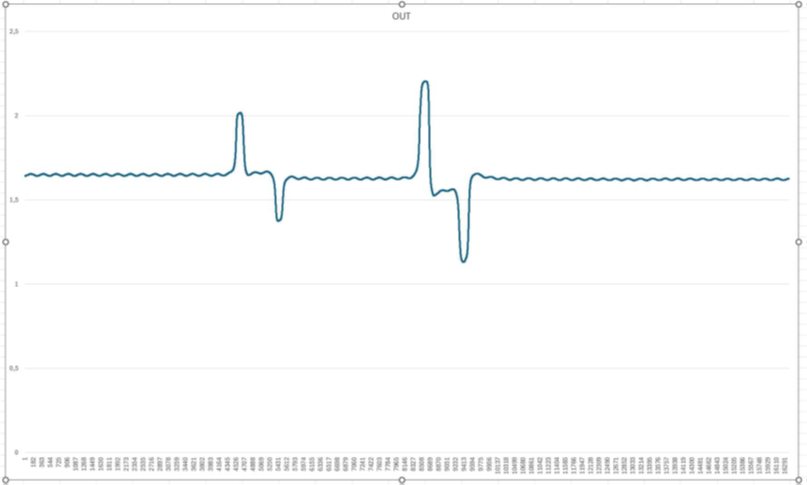

1.Ukutholwa Kwesiginali: Thatha amasignali okucindezela akhishwa izimoto ezidlulayo ezisebenzisa izinzwa ze-quartz, uguqule lawa masignali abe amasignali kagesi futhi uwathumele ohlelweni lokutholwa kwedatha.

2.Ukukhulisa Isignali Nokuhlunga: Khulisa futhi uhlunge izimpawu zikagesi ezitholiwe ukuze ususe umsindo nokuphazamiseka, ugcine ulwazi lwesisindo oluwusizo.

3.Ukwenza Idijithali: Guqula amasignali e-analog abe amasignali edijithali ukuze acutshungulwe futhi ahlaziywe.

4.Ukulungiswa Kwesisekelo: Yenza ukulungiswa kwesisekelo kumasiginali ukuze ususe i-zero-load offset, uqinisekise ukunemba kokulinganisa.

5.Ukuhlanganisa Ukucutshungulwa: Hlanganisa amasiginali alungisiwe ngokuhamba kwesikhathi ukuze ubale inani eliphelele, elilingana nesisindo semoto.

6.Ukulinganisa: Sebenzisa izici zokulinganisa ezinqunywe kusengaphambili ukuze uguqule inani leshajile libe amanani angempela esisindo.

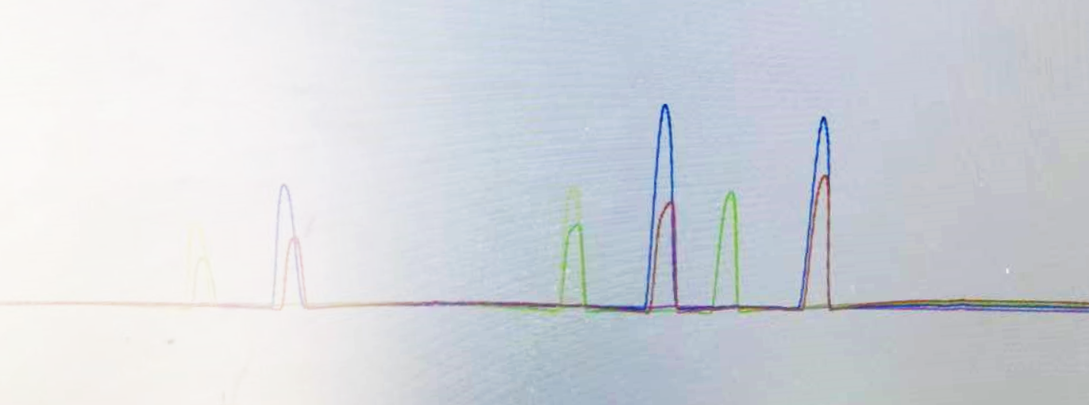

7.Isisindo Ukubala: Uma kusetshenziswa izinzwa eziningi, hlanganisa izisindo ezivela kunzwa ngayinye ukuze uthole isisindo semoto esiphelele.

Ubudlelwano phakathi kwama-algorithms nokunemba

Ukunemba kwesistimu ye-Weigh-In-Motion (WIM) kuncike kakhulu kuma-algorithms asetshenzisiwe. Izinzwa ze-quartz ze-Enviko ziqinisekisa ukunemba kokulinganisa isisindo ngokutholwa kwesignali enembe kakhulu nokucubungula. Ukunemba nokusebenza kahle kwama-algorithms okucubungula idatha kuthinta ngokuqondile imiphumela yokugcina yesisindo. Ukucubungula isignali okuthuthukisiwe nama-algorithms okuhlaziya idatha kungathuthukisa ngempumelelo ukunemba kwesisindo futhi kunciphise amaphutha okulinganisa.

Ngokukhethekile, ukunemba kokutholwa kwesignali, ukusebenza kahle kokuhlunga umsindo, nokunemba kokuhlanganisa nezinqubo zokulinganisa yizici ezibalulekile ezithinta ukunemba kwesisindo. Izinzwa ze-quartz ze-Enviko zihamba phambili kulezi zindawo, ziqinisekisa ukunemba okuphezulu nokuthembeka kwezinhlelo ze-WIM ngokusebenzisa ama-algorithms athuthukile kanye nehardware yekhwalithi ephezulu.

Ubudlelwano Phakathi Kokufaka Nokunemba

Ukuma kokufakwa kanye nendlela yezinzwa ze-quartz kuthinta kakhulu ukunemba kokulinganisa kohlelo lwe-WIM. Izinzwa kufanele zifakwe ezindaweni ezibalulekile endleleni yemoto ukuze kuqinisekiswe ukuthwebula okunembile kwezinguquko eziphezulu zengcindezi. Ngesikhathi sokufakwa, kubalulekile ukuqinisekisa ukuthintana okuseduze phakathi kwezinzwa nendawo yomgwaqo ukuze ugweme amaphutha okulinganisa ngenxa yokufakwa okungafanele.

Ukwengeza, izici zemvelo ezifana nezinga lokushisa, umswakama, nokucaba komhlaba kungase kuthinte ukusebenza kwenzwa nokunemba kokulinganisa. Nakuba izinzwa ze-quartz ze-Enviko zinokuzinza okuhle kakhulu kwezinga lokushisa, izinyathelo ezifanele zesinxephezelo zisadingeka ngaphansi kwezimo zokushisa ezeqisayo ukuze kuqinisekiswe imiphumela yokulinganisa enembile.

Ukulinganisa okuvamile nokunakekelwa kubalulekile ukuze kuqinisekiswe ukusebenza okuzinzile kwesikhathi eside kwezinzwa. Ngokufaka nokulungisa okuphrofeshinali, ukusebenza kwezinzwa ze-Enviko zequartz kungakhuliswa, kunikeze idatha enembile nethembekile yesisindo esiguqukayo (WIM).

Isiphetho

Ukusetshenziswa kwezinzwa ze-quartz ze-Enviko ezinhlelweni zokukala eziguqukayo (WIM) kunikeza izixazululo ezisebenza kahle nezithembekile zokulawulwa kwethrafikhi nokuvikelwa kwengqalasizinda. Ngokutholwa kwesignali enembile, ukucutshungulwa kwe-algorithm okuthuthukisiwe, nokufakwa nokugcinwa kochwepheshe, izinhlelo ze-quartz dynamic weighing (WIM) zingafinyelela ukuqapha kwesikhathi sangempela nokuphathwa kwesisindo semoto, zehlise ngempumelelo ukuguga komgwaqo namabhuloho futhi zithuthukise ukusebenza kahle kokuphathwa kwethrafikhi. Ngokuthuthuka okuqhubekayo kwezobuchwepheshe, izinzwa ze-quartz ze-Enviko zizodlala indima ebaluleke kakhulu ezinhlelweni ze-WIM, zinikeze isisekelo esiqinile sokuthuthukiswa kwezokuthutha ezihlakaniphile.

Inkampani engu-Enviko Technology Co., Ltd

E-mail: info@enviko-tech.com

https://www.envikotech.com

Ihhovisi laseChengdu: No. 2004, Unit 1, Building 2, No. 158, Tianfu 4th Street, Hi-tech Zone, Chengdu

Ihhovisi laseHong Kong: 8F, Cheung Wang Building, 251 San Wui Street, Hong Kong

Isikhathi sokuthumela: Aug-07-2024