1. Ubuchwepheshe Basemuva

Njengamanje, amasistimu e-WIM asekelwe kuzinzwa zesisindo se-quartz ye-piezoelectric asetshenziswa kabanzi kumaphrojekthi afana nokuqapha ukugcwala kakhulu kwamabhuloho nama-culverts, ukuphoqelela ukulayishwa ngokweqile kwesayithi kwezimoto ezithwala izimpahla zomgwaqo onguthelawayeka, nokulawula ukugcwala ngokweqile kobuchwepheshe. Kodwa-ke, ukuze kuqinisekiswe ukunemba nempilo yesevisi, amaphrojekthi anjalo adinga ukwakhiwa kabusha komgwaqo ogandaywe ngosimende wendawo ye-piezoelectric quartz enesisindo sokufakwa kwezinzwa nezinga lobuchwepheshe lamanje. Kodwa kwezinye izindawo ezisetshenziswayo, njengamadekhi amabhuloho noma imigwaqo emikhulu yasemadolobheni enomfutho wethrafikhi osindayo (lapho isikhathi sokulungisa usimende siside kakhulu, okwenza ukuvalwa kwemigwaqo yesikhathi eside kube nzima), amaphrojekthi anjalo anzima ukuwenza.

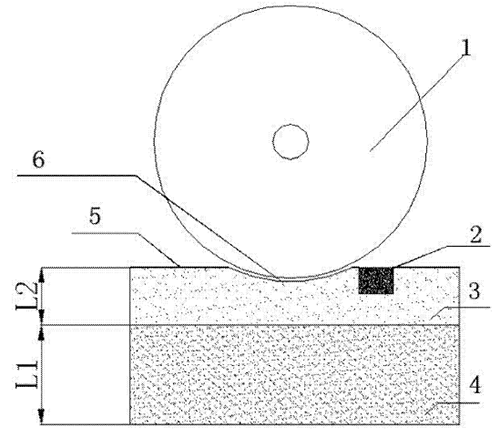

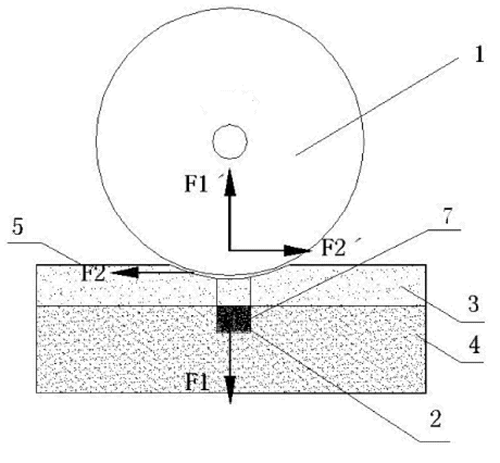

Isizathu sokuthi izinzwa ezinesisindo se-piezoelectric quartz azikwazi ukufakwa ngokuqondile ku-pavement eguquguqukayo yilezi: Njengoba kuboniswe kuMfanekiso 1, lapho isondo (ikakhulukazi ngaphansi komthwalo osindayo) lihamba endaweni egandayiwe eguquguqukayo, indawo yomgwaqo izoba nendawo encane kakhulu. Kodwa-ke, lapho ufinyelela endaweni yenzwa enesisindo se-piezoelectric quartz, izici eziphansi zenzwa kanye nendawo yokusebenzela egandayiwe ziyahluka. Ngaphezu kwalokho, inzwa enesisindo esiqinile ayinakho ukunamathela okuvundlile, okubangela ukuthi inzwa yokukala iphuke ngokushesha futhi ihlukane nomgwaqo.

(isondo elingu-1, inzwa enesisindo esingu-2, isendlalelo sesisekelo esithambile esingu-3, isendlalelo sesisekelo esiqinile esingu-4, indlela egandayiwe eguquguqukayo engu-5, indawo engaphansi kwe-6, i-7-foam pad)

Ngenxa yezici ezihlukene zokuncibilika kanye nama-coefficients ahlukene okungqubuzana komgwaqo, izimoto ezidlula inzwa ye-piezoelectric quartz enesisindo zithola ukudlidliza okunzima, okuthinta ngokuphawulekayo ukunemba kukonke kwesisindo. Ngemuva kokucindezelwa kwemoto isikhathi eside, isayithi lijwayele ukulimala nokuqhekeka, okuholela ekulimaleni kwezinzwa.

2. Isixazululo Samanje Kule Nsimu: Ukwakhiwa Kabusha Kwe-Pavement Kasimende

Ngenxa yenkinga yezinzwa zesisindo se-quartz ye-piezoelectric azikwazi ukufakwa ngokuqondile ku-asphalt pavement, isilinganiso esivame ukutholwa embonini ukwakhiwa kabusha komgwaqo ogandaywe ngosimende wendawo yokufaka inzwa ye-piezoelectric quartz enesisindo. Ubude obujwayelekile bokwakha kabusha bungamamitha ayi-6-24, ububanzi obulingana nobubanzi bomgwaqo.

Nakuba ukwakhiwa kabusha komgwaqo ogandaywe ngosimende kuhlangabezana nezidingo zamandla zokufaka izinzwa zesisindo se-quartz ye-piezoelectric futhi kuqinisekisa impilo yesevisi, izinkinga ezimbalwa zikucindezela kakhulu ukukhuthazwa kwakho okusabalele, ikakhulukazi:

1) Ukwakhiwa kabusha kukasimende okuqinile komgwaqo wokuqala kudinga inani elikhulu lezindleko zokwakha.

2) Ukwakhiwa kabusha kukasimende kudinga isikhathi eside kakhulu sokwakha. Isikhathi sokulungisa indawo egandaywe ngosimende sisodwa sidinga izinsuku ezingama-28 (imfuneko evamile), ngokungangabazeki okubangela umthelela omkhulu ekuhlelweni kwethrafikhi. Ikakhulukazi kwezinye izimo lapho izinhlelo ze-WIM zidingeka khona kodwa ukuhamba kwethrafikhi kuphezulu kakhulu, ukwakhiwa kwephrojekthi kuvame ukuba nzima.

3) Ukucekelwa phansi kwesakhiwo somgwaqo sokuqala, okuthinta ukubukeka.

I-4) Ukushintsha okungazelelwe kuma-coefficients e-friction kungabangela izenzakalo ze-skidding, ikakhulukazi ezimweni zemvula, ezingaholela kalula ezingozini.

5) Izinguquko zesakhiwo somgwaqo zibangela ukundindizela kwezimoto, okuthinta ukunemba kwesisindo ngokwezinga elithile.

6) Ukwakhiwa kabusha kukasimende ngeke kuqaliswe kweminye imigwaqo ethile, njengamabhuloho aphakeme.

7) Njengamanje, emkhakheni wethrafikhi yomgwaqo, ukuthambekela kusuka kwabamhlophe kuye kwabamnyama (ukuguqula umgwaqo usimende ube umgwaqo wetiyela). Isixazululo samanje sisuka kokumnyama siye kokumhlophe, esingahambelani nezidingo ezifanele, futhi amayunithi okwakha avame ukumelana.

3. Okuqukethwe Kwesu Lokufaka Okuthuthukisiwe

Inhloso yalolu hlelo ukuxazulula ukushoda kwezinzwa zesisindo se-piezoelectric quartz ezingakwazi ukufakwa ngokuqondile endaweni egandaywe yi-asphalt kakhonkolo.

Lolu hlelo lubeka ngokuqondile inzwa yesisindo se-quartz ye-piezoelectric kusendlalelo sesisekelo esiqinile, igwema inkinga yesikhathi eside yokungahambelani ebangelwa ukushumeka okuqondile kwesakhiwo senzwa eqinile endaweni egandayiwe eguquguqukayo. Lokhu kwandisa kakhulu impilo yesevisi futhi kuqinisekisa ukuthi ukunemba kwesisindo akuthinteki.

Ngaphezu kwalokho, asikho isidingo sokwakha kabusha indawo egandaywe ngosimende endaweni egandaywe yitiyela yasekuqaleni, konga inani elikhulu lezindleko zokwakha futhi kufinyezwe kakhulu isikhathi sokwakha, kunikeze ithuba lokukhushulwa okukhulu.

Umfanekiso wesi-2 uwumdwebo oyisikimu wesakhiwo onenzwa yesisindo se-quartz ye-piezoelectric ebekwe kungqimba oluthambile lwesisekelo.

(isondo elingu-1, inzwa enesisindo esingu-2, isendlalelo sesisekelo esithambile esingu-3, isendlalelo sesisekelo esiqinile esingu-4, indlela egandayiwe eguquguqukayo engu-5, indawo engaphansi kwe-6, i-7-foam pad)

4. Ubuchwepheshe Obubalulekile:

1) Ukumbiwa kwangaphambili kwesakhiwo sesisekelo ukuze kwakhiwe indawo yokwakha kabusha, ene-slot ejulile engama-24-58 cm.

2) Ukulinganisa phansi kwe-slot kanye nokuthulula impahla yokugcwalisa. Isilinganiso esinqunyiwe sesihlabathi se-quartz + i-stainless steel sand epoxy resin sithululelwa ngaphansi kwe-slot, sigcwaliswe ngokulinganayo, ngokujula kokugcwalisa okungu-2-6 cm futhi kulinganiswe.

3) Ukuthulula isendlalelo sesisekelo esiqinile nokufaka inzwa yokukala. Thela isendlalelo sesisekelo esiqinile bese ushumeka inzwa yokukala kuso, usebenzisa i-foam pad (0.8-1.2 mm) ukuze uhlukanise izinhlangothi zenzwa yesisindo kusukela kusendlalelo sesisekelo esiqinile. Ngemuva kokuthi isendlalelo sesisekelo esiqinile siqinile, sebenzisa igrinda ukuze ugaye inzwa yesisindo kanye nesendlalelo sesisekelo esiqinile endizeni efanayo. Isendlalelo sesisekelo esiqinile singaba isendlalelo sesisekelo esiqinile, esingaqinile, noma esiyinhlanganisela.

4) Ukusakaza kwesendlalelo esingaphezulu. Sebenzisa okubalulekile okuhambisana nongqimba oluyisisekelo oluguquguqukayo ukuze uthele futhi ugcwalise ubude obusele be-slot. Phakathi nenqubo yokuthela, sebenzisa umshini omncane wokuhlanganisa ukuze uhlangane kancane, uqinisekise izinga eliphelele lendawo eyakhiwe kabusha nezinye izindawo zomgwaqo. Isendlalelo sesisekelo esishintshashintshayo siwungqimba lwe-asphalt oluyimbudumbudu oluphakathi nendawo.

5) Isilinganiso sogqinsi sesendlalelo sesisekelo esiqinile ukuya kungqimba oluyisisekelo oluguquguqukayo ngu-20-40:4-18.

Inkampani engu-Enviko Technology Co., Ltd

E-mail: info@enviko-tech.com

https://www.envikotech.com

Ihhovisi laseChengdu: No. 2004, Unit 1, Building 2, No. 158, Tianfu 4th Street, Hi-tech Zone, Chengdu

Ihhovisi laseHong Kong: 8F, Cheung Wang Building, 251 San Wui Street, Hong Kong

Ifekthri: Isakhiwo 36, Indawo Yezimboni yaseJinjialin, Idolobha laseMianyang, Isifundazwe saseSichuan

Isikhathi sokuthumela: Apr-08-2024