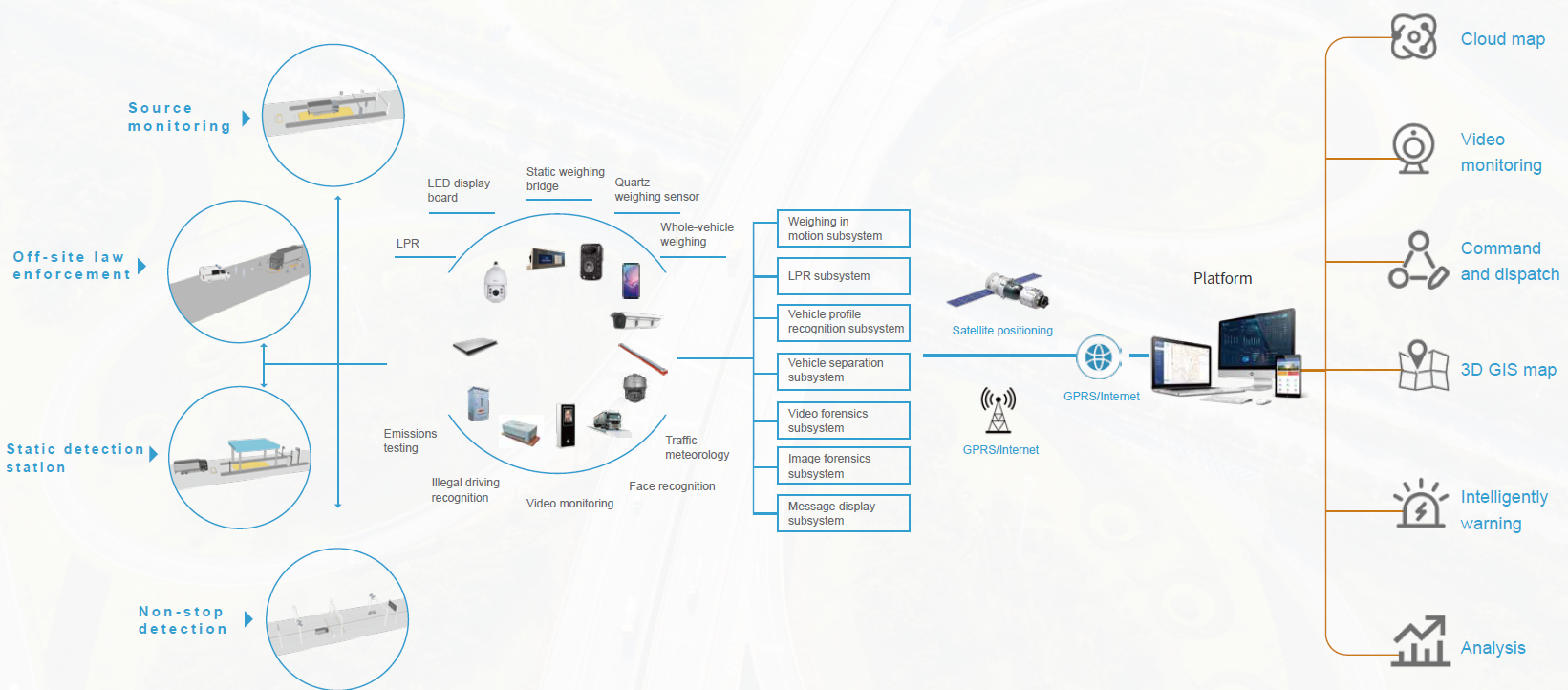

I-Enviko Quartz Dynamic Weighing System (Enviko WIM system) iyisistimu yokukala enembayo ephezulu esekelwe kuzinzwa ze-quartz, esetshenziswa kabanzi emkhakheni wezokuthutha. Lolu hlelo lusebenzisa izinzwa ze-quartz ze-Enviko ukukala isisindo esiguqukayo sezimoto ngesikhathi sangempela, ngaleyo ndlela kuzuzwe ukuqapha okunembile kwemithwalo yezimoto. Lolu hlelo lubonakala ngokunemba okuphezulu, ukwethembeka, nokuqina, lusiza ngempumelelo ekuphatheni ukuthuthwa komgwaqo kanye nokugcina ingqalasizinda yomgwaqo.

Izinzuzo

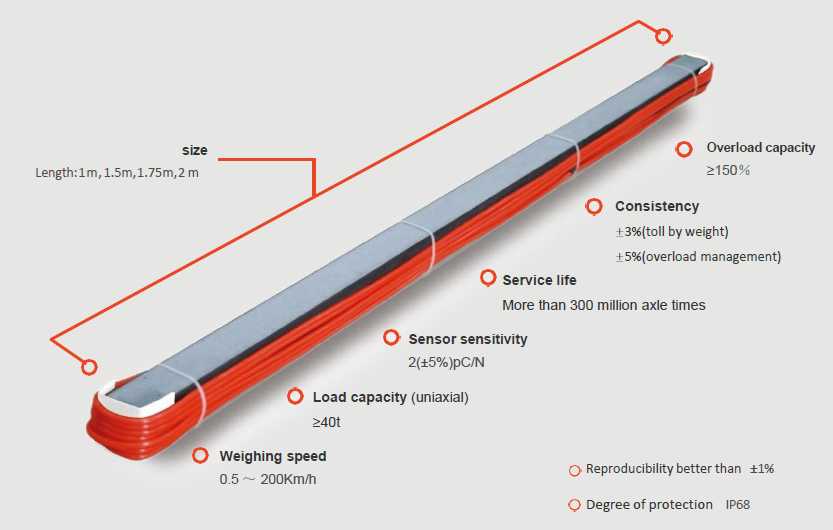

1.Ukunemba okuphezulu: I-Enviko Quartz Dynamic Weighing System isebenzisa izinzwa ze-quartz ze-Enviko, ezinokuzwela okuphezulu kakhulu nokunemba, okuvumela ukukala isisindo semoto okunembile kanye nokudluliswa kwedatha ngesikhathi sangempela.

2.Ukuqina: Izinzwa ze-quartz ze-Enviko zenziwe ngezinto ezisezingeni eliphezulu ezinokumelana okuhle kakhulu kokugqoka kanye nokumelana nokucindezela, okuqinisekisa ukusebenza okuzinzile kwesikhathi eside ezindaweni zomgwaqo ezinzima.

3.Ukufaka Easy: Inqubo yokufaka i-Enviko Quartz Dynamic Weighing System ilula uma kuqhathaniswa. Ngokulandela izinyathelo ezithile zokufaka, isistimu ingasatshalaliswa futhi ilungiswe kahle.

4.Ukuqapha Isikhathi Sangempela: Uhlelo lungaqapha idatha yesisindo semoto ngesikhathi sangempela futhi ludlulisele idatha kusistimu yokulawula emaphakathi ngobuchwepheshe bokudlulisa okungenantambo, lula ukuhlaziya idatha kanye nokwenza izinqumo ngabaphathi.

5.Ukusebenza Okuningi: Ngaphezu kokukala, i-Enviko Quartz Dynamic Weighing System iphinde ibe nokuhlonza imoto, ama-alamu agcwele kakhulu, nokunye, okuhlinzeka ngezixazululo ezibanzi zokulawulwa kwethrafikhi.

Izinyathelo Zokufaka kanye Nezindlela

Izidingo Zobuchwepheshe Zocwaningo Lwesayithi

1.Ukukhetha Indawo Yesisindo: Qinisekisa ukuthi indawo yesisindo iyingxenye yomgwaqo eqondile engamamitha angu-200-400 ngaphambi nangemuva kwesiteshi sokukala, ezingenazo iziphambano zomgwaqo, ukuze kuqinisekiswe ukuthobela kwemoto ngaphakathi kwendawo yokukala nokuthuthukisa ukunemba kwesisindo.

2.Ukufakwa kwesibonisi se-LED: Kunconywa ukufaka isibonisi se-LED ngamamitha angu-250-500 ngemuva kwendawo yokukala ukuze kube lula abashayeli ekubukeni ulwazi lwesisindo.

3.Gwema Amajika Nemithambeka: Khetha izigaba zomgwaqo eziqondile zokwakhiwa futhi ugweme ukufaka isistimu yokukala kumajika nemithambeka.

Izidingo Zobuchwepheshe Zokwakheka Kwenzwa

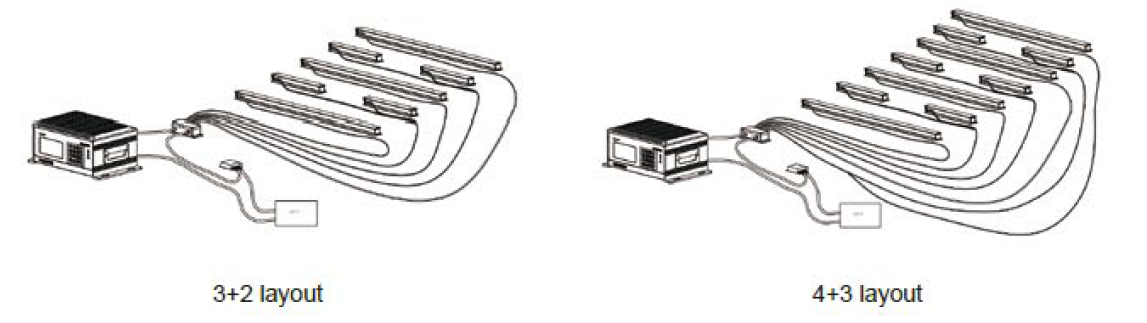

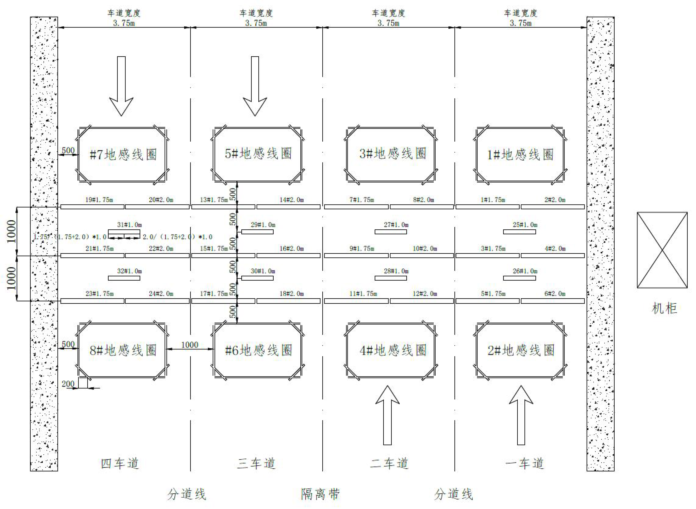

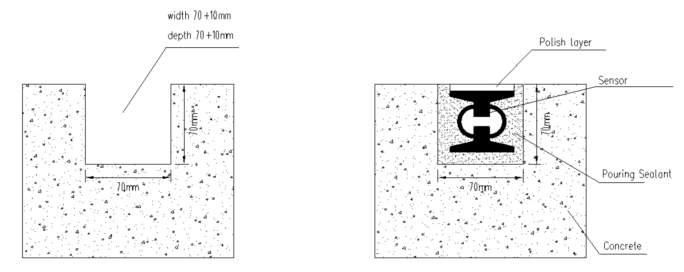

Izinzwa ze-Enviko Quartz Dynamic Weighing System zisebenzisa isakhiwo esithi "3+2", esinemigqa emithathu ebekwe ngokugcwele, nebanga eliyimitha elingu-1 phakathi komugqa ngamunye wezinzwa. Maphakathi nemigqa emithathu, kubekwa inzwa enobude obuyimitha elingu-1 (ngobubanzi bomzila owodwa obungaphansi kwamamitha angu-4.25) noma amamitha angu-1.5 (ngobubanzi bomzila owodwa ngaphezu kwamamitha angu-4.25) kubekwa ngaphandle. Ubude bezinzwa lusatshalaliswa ngokulinganayo futhi buqondaniswe neziphetho zezinzwa ezigcwele irowu, nesikhala esingamamitha angu-0.5.

Ukuguqulwa Kwendawo Yomgwaqo

1.Imibandela Yokwakha: Qedela ukuvalwa kwemigwaqo nomsebenzi wokuphambukisa izimoto ukuze kuqinisekiswe ukulungela kwezinto zokwakha nezinto zokwakha.

2.Inqubo yokwakha:

·Isilinganiso kanye Nokumaka: Linganisa futhi umaka ngokusho kwemidwebo yokuklama ukuze uqinisekise ukunemba kwendawo yokwakha.

·Ukusika Nokugqekeza Umgwaqo: Sebenzisa umshini wokusika umgwaqo ukuze usike indawo ezungezile, ngokujula kokusika okukhulu kuno-10 cm, bese uphula indawo yomgwaqo.

·Ukuhlanza isisekelo kanye nokubeka izinga: Hlanza umgodi wesisekelo futhi uwuleveli usebenzisa ileveli ne-theodolite ukuze uqinisekise ukucaba.

·Ukuthela Ukhonkolo: Thela ukhonkolo ngokuvumelana nezidingo zokuklama, uqinisekise ukuthi ukhonkolo wesendlalelo sesisekelo uthululelwa ngesikhathi esisodwa, futhi wenze ukudlidliza nokwelashwa kwendawo.

·I-Rebar Processing: Beka futhi ubophe i-rebar ngokwemidwebo yokuklama, uqinisekise ukunemba nokuzinza kwe-rebar mesh.

Inqubo yokufaka inzwa kanye nezimfuneko zobuchwepheshe

1.Ukuqinisekisa Isimo Senzwa: Qinisekisa indawo yokufaka yezinzwa ze-quartz ze-Enviko ngokuya ngemidwebo yokuklama bese uyimaka.

2.Ukufakwa kwenzwa:

·Ukufakwa Kwesisekelo: Faka isisekelo sezinzwa kusisekelo sikakhonkolo esithululiwe, uqinisekise ukuthi isisekelo sisezingeni futhi sivikelekile.

·Ukulungiswa Kwenzwa: Lungisa izinzwa ze-quartz ze-Enviko esisekelweni futhi wenze ukulungisa iphutha kwasekuqaleni ukuze uqinisekise ukuthi izinzwa zisebenza kahle.

3.Uxhumano Lwekhebula Yedatha: Xhuma izintambo zedatha yenzwa bese ubeka izintambo ohlelweni lokulawula olumaphakathi, uqinisekise ukudluliswa kwedatha okuzinzile.

4.Ukulungisa iphutha lesistimu: Yenza ukulungisa amaphutha okuphelele kwalo lonke uhlelo ukuze uqinisekise ukusebenza okuvamile kwe-Enviko Quartz Dynamic Weighing System.

Isiphetho

I-Enviko Quartz Dynamic Weighing System (Uhlelo lwe-Enviko WIM), nokunemba kwayo okuphezulu, ukuqina, nokusebenza okuningi, iba yithuluzi elibalulekile lokuphatha ezokuthutha emgwaqeni. Ngokulandela ngokuqinile izinyathelo nezindlela ezivezwe encwadini yokufaka, ukusebenza okuzinzile kwesistimu kanye nokulinganisa okunembile kungaqinisekiswa. Ukusebenza kwezinzwa zequartz ze-Enviko, njengengxenye eyinhloko yesistimu, kuthinta ngokuqondile ukunemba nokuthembeka kwesistimu. Ngakho-ke, ngesikhathi sokufakwa nokusetshenziswa, kubalulekile ukusebenza ngokwezidingo zobuchwepheshe ukuze usebenzise ngokugcwele izinzuzo ze-Enviko Quartz Dynamic Weighing System (Uhlelo lwe-Enviko WIM).

Inkampani engu-Enviko Technology Co., Ltd

E-mail: info@enviko-tech.com

https://www.envikotech.com

Ihhovisi laseChengdu: No. 2004, Unit 1, Building 2, No. 158, Tianfu 4th Street, Hi-tech Zone, Chengdu

Ihhovisi laseHong Kong: 8F, Cheung Wang Building, 251 San Wui Street, Hong Kong

Isikhathi sokuthumela: Aug-07-2024