Okokuqala, ukwakheka kwesistimu

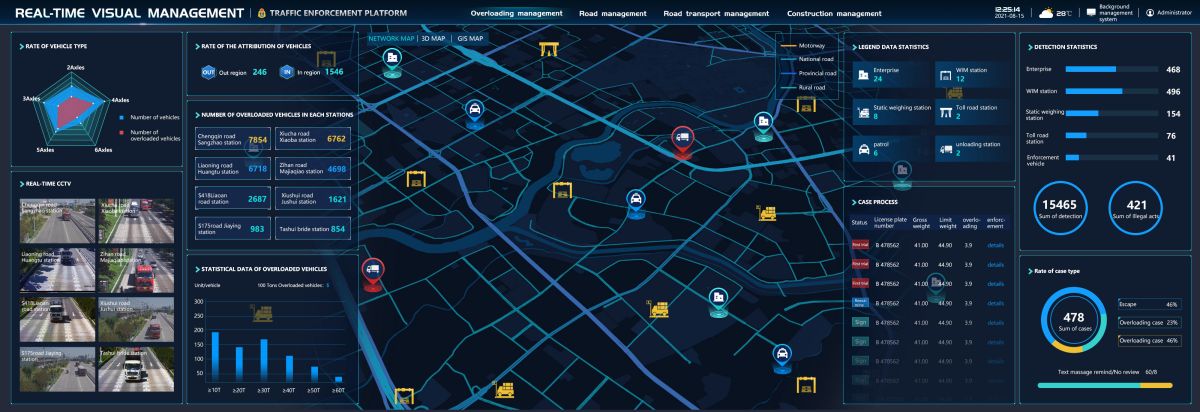

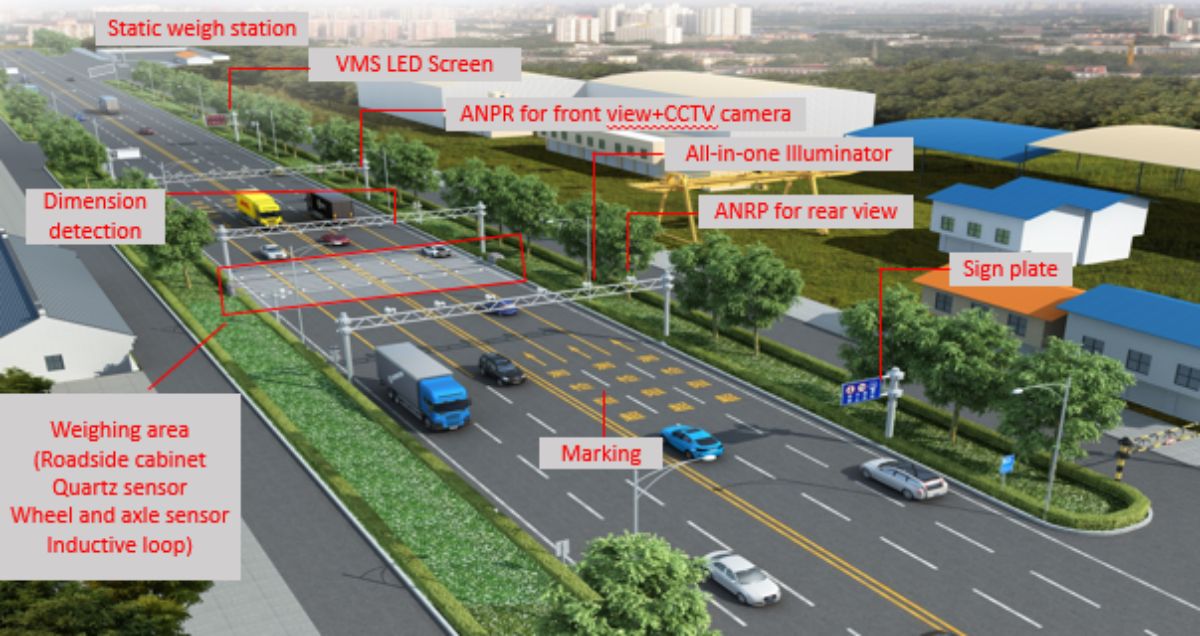

1.Uhlelo lokubona ukulayishwa ngokweqile komgwaqo onguthelawayeka lungami ngokuvamile lwakhiwe ukuqoqwa kolwazi olugcwele kakhulu lwemoto ethwala impahla engaphambili kanye nesistimu yezobunhloli kanye nokulawulwa kolwazi lwemoto ethwala impahla engemuva.

2. Iqoqo lemininingwane yemoto ethwala impahla engaphambili engaphambili kanye nesistimu yezobunhloli ngokuvamile yakhiwa izinto zokukala ezingami, okokusebenza kokubona usayizi wephrofayili yemoto, ukuqashelwa kwepuleti lelayisense kanye nemishini yokuthwebula, umtshina wemoto, okokusebenza kwevidiyo okugada, okokukhipha imininingwane, izimpawu zomgwaqo, ugesi kanye nezindawo zokuvikela umbani, amakhabethe okulawula asendaweni, ukuqoqwa kolwazi kanye nokutholwa kwesisindo sendawo kanye nezindawo zokudlulisa izimpawu zenethiwekhi izinsiza ezihambisanayo ezisekelayo.

3. Inkundla yokuphathwa kolwazi lwezimoto ezithwala impahla engemuva kokugcina (kuhlanganise nomthetho oqondile) inkundla ngokuvamile yakhiwa izinkundla zesifunda (isifunda), zikamasipala nezesifundazwe zokuphatha ulwazi olugcwele (okuhlanganisa nokuphoqelela umthetho).

2. Izidingo zokusebenza

1. Izidingo zokusebenza zemishini yokukala engami

1.1 Ibanga lesivinini sokusebenza

Ibanga lejubane lempahla yokukala engami lingu-(0.5~100) km/h ukuze izimoto ezithwala impahla zidlule endaweni etholwayo engami.

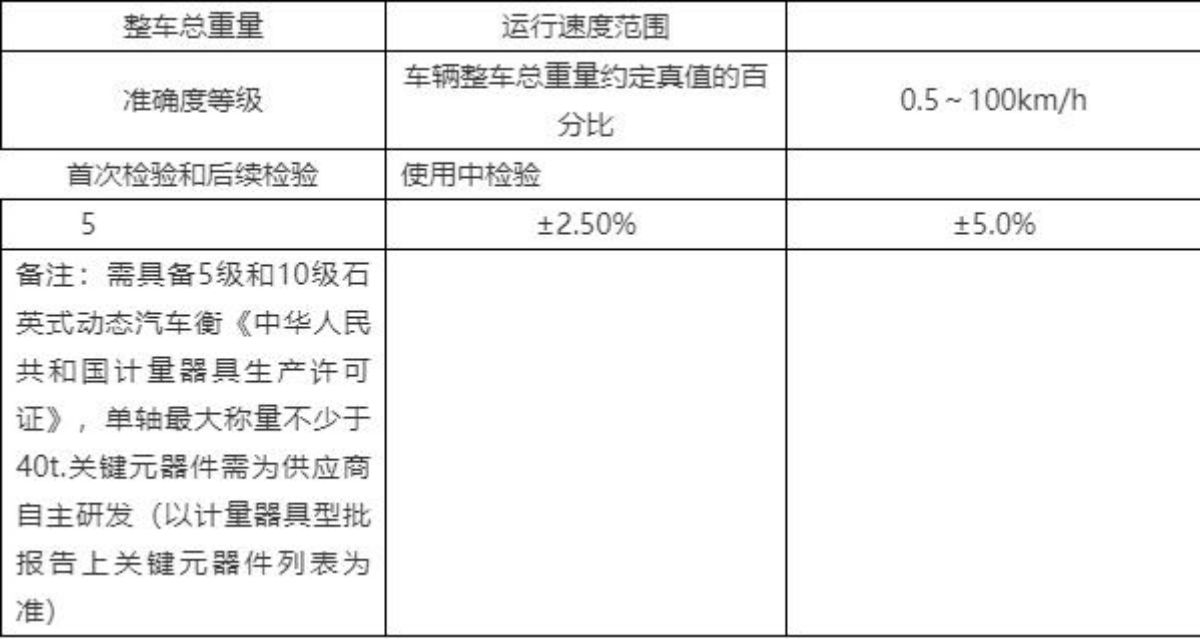

1.2 Izinga lokunemba lengqikithi yesisindo semoto

(1) Iphutha eliphakeme elivumelekile lokukala isisindo semoto nempahla ngaphakathi kwebanga lejubane elivumelekile lempahla yesisindo esingami ngeke libe ngaphansi kwezinhlinzeko nezimfuneko zezinga lokunemba 5 kanye nele-10 ku-JJG 907 "I-Dynamic Highway Vehicle Automatic Weighing Apparatus"1(I-Tification Regulations2).

Ithebula 2-1 Iphutha elikhulu elivumelekile lesisindo esiguqukayo sesisindo semoto esiphelele

(2) Lapho imoto ethwala impahla idlula endaweni okutholakala kuyo ukukala isisindo esingami nemikhuba yokushayela engavamile njengokusheshisa njalo nokwehla, isikali sokugxuma, ukuma, ukugoba u-S, ukuwela, ulayini wokucindezela, ukushayela emuva noma ukuma nokuhamba ngesikhathi esifushane, izinga lokunemba lesisindo esiphelele semoto ye-non-stop dinner ngeke libe phansi kunezimfuneko ze-non-stop. 2-1. (Ukucindezela imizila nokushayela kwelinye icala kubalulekile).

1.3 Iseli elithwalayo elisetshenziswa kumshini wokukala ongami kufanele lihambisane nezinhlinzeko nezimfuneko ze-GB/T7551 "Iseli Lokulayisha", impilo yesevisi izoba ≥ ama-asi ayizigidi ezingu-50, futhi izinga lokuvikela leseli lomthwalo elisetshenziswa esikalini esingami akumele libe ngaphansi kwe-IP68. .

1.4 Isilinganiso sesikhathi sokusebenza esingenazinkinga semishini yokukala engami akumele sibe ngaphansi kuka-4000h, futhi isikhathi sewaranti sezingxenye ezibalulekile ngeke sibe ngaphansi kweminyaka emi-2, futhi impilo yesevisi ngeke ibe ngaphansi kweminyaka emi-5.

1.5 Izidingo zokuvikela ukucisha

(1) Uma ugesi ucishiwe, okokusebenza kwesisindo okungami kufanele kukwazi ukugcina ngokuzenzakalelayo amapharamitha asethiwe njengamanje nolwazi lwesisindo, futhi isikhathi sokugcina akufanele sibe ngaphansi kuka-72h.

(2) Endabeni yokwehluleka kwamandla, isikhathi sokusebenza kwewashi langaphakathi lempahla yokukala engami akumele sibe ngaphansi kwama-72d.

1.6 Izidingo zokwelashwa kokuqeda ukugqwala

Izingxenye zensimbi eziveziwe zemishini yokukala engami kufanele ziphathwe ngomuthi wokunqanda ukugqwala ngokuhambisana nezinhlinzeko ezifanele ze-GB/T18226 "Technical Conditions for Anti-corrosion of Steel Components in Highway Traffic Engineering".

1.7 Iphutha lesilinganiso sejubane lomtshina wemoto wempahla yokukala engami kufanele ibe ≤± 1km/h, futhi ukunemba kokutholwa kokugeleza kwethrafikhi kufanele kube ≥99%.

1.8 Izidingo zobuchwepheshe zezihlukanisi zezimoto zezimpahla zokukala ezingami zimi kanje:

(1) Ukunemba kokutholwa kwenombolo yezimbazo kufanele kube ≥98%.

(2) Iphutha lokuthola isikhala se-shaft kufanele libe ≤± 10cm.

(3) Ukunemba kokuhlukaniswa kwezimoto kufanele kube ≥ 95%.

(4) Izinga lokuqashelwa kwesiteshi esiphambanayo kufanele libe ngu-≥98%.

1.9 Ububanzi obusebenzayo bezinga lokushisa kwendawo yokusebenza kufanele bufinyelele -20°C~+80°C, futhi izinkomba zobuchwepheshe zokumelana nokuswakama kwemvelo kufanele zihlangabezane nemithetho nezidingo ezifanele zemishini yangaphandle nemishini kagesi ye-JT/T817 "Izimfuneko Zobuchwepheshe Ezijwayelekile Nezindlela Zokuhlola Zesisetshenziswa Sesistimu Ye-Electromechanical System".

1.10 Izinyathelo zokuvikela imvula nezokuvikela kufanele zithathwe, futhi izinga lokuvikela kufanele lihlangabezane nezinhlinzeko nezimfuneko ze-JT/T817.

2. Izidingo zokusebenza zemishini yokuhlola usayizi wephrofayela yemoto

2.1 Uma imoto yomthwalo idlula endaweni yokuthola isisindo esingami ngesivinini esingu-(0.5~100) km/h, kufanele ikwazi ukuqedela ngokuzenzakalela ukutholwa okusheshayo kwesikhathi sangempela kobukhulu bejiyomethri kanye nemodeli ye-3D yobude, ububanzi nobude bemoto yomthwalo, futhi ikhiphe imiphumela yokuhlonza efanele. Isikhathi sokuphendula akufanele sibe ngaphansi kuka-30ms, futhi isikhathi sokuqedela ukutholwa okukodwa kanye nomphumela wokuphumayo akufanele sibe ngaphezu kwama-5s.

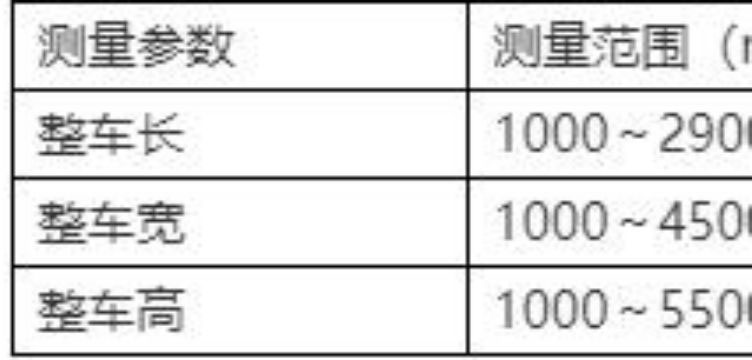

2.2 Ibanga lokulinganisa lejiyomethri lobude, ububanzi nobude bemoto yomthwalo lizohlangabezana nezidingo zeThebula 2-2.

Ithebula 2-2 Ibanga lokulinganisa lempahla yokuhlola usayizi wephrofayela yemoto

2.3 Isixazululo sesilinganiso sobukhulu bejiyomethri sobude, ububanzi nobude bemoto ethwala impahla abukho ngaphezu kuka-1mm, futhi iphutha lesilinganiso semishini yokuthola usayizi wohlaka lwemoto kufanele lihlangabezane nezimfuneko ezilandelayo ngaphakathi kwebanga elingu-1~100km/isivinini sokusebenza esivamile: (ngokwejubane lokugijima, kufanele lihambisane nezidingo zemishini yokukala eguqukayo yangaphambilini).

(1) Iphutha lobude≤±500mm;

(2) Iphutha lobubanzi≤±100mm;

(3) Iphutha lokuphakama ≤± 50mm.

2.4 Imvamisa yokutholwa kwendawo nge-laser yemishini yokuhlola usayizi wephrofayela yemoto kufanele ibe ngu-≥1kHz, futhi kufanele ibe nezinhlobo ezingu-9 zamamodeli emoto nemisebenzi yokutholwa kwesivinini semoto ecaciswe emotweni engu-GB1589 "Usayizi Wohlaka, Umthwalo we-Axle kanye Nemikhawulo Yekhwalithi Yezimoto, Ama-trailer kanye Nezitimela Zezimoto".

2.5 Kufanele ibe nemisebenzi yezimoto ezithuthwayo ezihambisanayo, ukwahlulela kwesimo sokushayela kwe-S-bend, isivikelo esibalulekile esimnyama kanye nephrofayili yemoto yempahla ekhanyayo ekhanyayo yejiyomethri.

2.6 kufanele ibe nesigaba samamodeli ezimoto ezithwala impahla, umthamo wethrafikhi, isivinini sendawo, ibanga lesikhathi sangaphambili, ngokulandela iphesenti lemoto, isikhala sangaphambili, imisebenzi yokuthola isikhathi. Futhi ukunemba kwezigaba zamamodeli wezimoto ezithwala impahla kufanele kube ≥ 95%.

2.7 Ibanga elisebenzayo lokushisa kwendawo yokusebenza kufanele lihlangabezane -20 °C ~ +55 °C, futhi izinkomba zobuchwepheshe zokumelana nokuswakama kwemvelo kufanele zihlangabezane nemithetho nezidingo ezifanele zemishini yangaphandle nemishini kagesi ye-JT/T817 "Izimfuneko Zobuchwepheshe Ezijwayelekile kanye Nezindlela Zokuhlola Zesisetshenziswa Sesistimu Se-Electromechanical System".

2.8 Izinto zokuhlola usayizi wephrofayela yemoto ye-laser kufanele zifakwe ne-gantry eneshaneli yokulungisa

2.9 Izinga lokuvikela lezinto zokuhlola usayizi wephrofayela yemoto akufanele libe ngaphansi kwe-IP67.

3. Izidingo zokusebenza zokuqashelwa kwepuleti lelayisense nokokusebenza kokuthwebula

3.1 Izidingo zokusebenza zokuqashelwa kwepuleti lelayisense kanye nokokusebenza kokuthwebula kuzohlangabezana nezinhlinzeko nezimfuneko ze-GB/T 28649 "Isistimu Yokuhlonza Okuzenzakalelayo Yezinombolo Zezimoto".

3.2 Imishini yokuqashelwa kwepuleti lelayisense kanye nokuthwebula kufanele ifakwe isibani sokugcwalisa noma isibani esikhanyayo, esizokwazi ukuthwebula ngokucacile inombolo yemoto edlula endaweni yokuthola isisindo esingami ngaphansi kwanoma yiziphi izimo zezulu, futhi ikhiphe umphumela wokuhlonza olungile.

3.3 Ukuqashelwa kwepuleti lelayisense nokokusebenza kokuthwebula kufanele ≥ 99% wokunemba kokuqashelwa kwepuleti lelayisense phakathi nosuku, kanye nokunemba okungu-≥95% kokuqashelwa kwepuleti lelayisense ebusuku, futhi isikhathi sokuqashelwa akufanele sibe ngaphezu kwama-300ms.

3.4 Isithombe sepuleti lenombolo yemoto eqoqiwe kufanele sikhishwe ngokucacile ngefomethi ye-JPG yobubanzi obugcwele, futhi umphumela wokuqashelwa kufanele uhlanganise isikhathi sokuqashelwa, umbala wepuleti lelayisense, njll.

3.5 amaphikseli wesithombe sokuqashelwa kwepuleti lelayisense akufanele abe ngaphansi kwezigidi ezingu-5, amanye amaphikseli wesithombe sokuthwebula akufanele abe ngaphansi kwezigidi ezingu-3, izimoto ezithwala impahla ngendawo yokuthola isisindo esingami, kufanele zithwebule ingaphambili lemoto, izinhlangothi ezimbili zemoto kanye nengemuva lemoto ingqikithi yezithombe ezingekho ngaphansi kwezingu-4 ezinencazelo ephezulu.

13 ngokolwazi lwesithombe olunencazelo ephezulu yengemuva lemoto, inombolo yepuleti lelayisense yomsila, umbala womzimba nolunye ulwazi lungahlukaniswa.

3.7 Isithombe ngasinye kufanele sibekwe ngaphezu kolwazi olufana nosuku lokutholwa, isikhathi sokuhlola, indawo yokuhlola, isisindo esiphelele semoto nempahla, ubukhulu bemoto, inombolo yempahla ye-forensics yesithombe, ukulwa nomgunyathi nolunye ulwazi.

3.8 Umkhawulokudonsa wesiteshi sokudlulisa ulwazi lwesithombe esithathiwe akufanele ube ngaphansi kuka-10Mbps.

3.9 Kufanele ibe nemisebenzi yokuzihlola enephutha njengokuxhumana okungavamile kanye nokuhluleka kwamandla.

3.10 Ibanga elisebenzayo lokushisa kwendawo yokusebenza kufanele lifinyelele -20 °C ~ +55 °C, futhi izinkomba zobuchwepheshe zokumelana nokuswakama kwemvelo kufanele zihlangabezane nemithethonqubo efanelekile kanye nezidingo zemishini yangaphandle yezinto zokusebenza zikagesi ze-JT/T817 "Izimfuneko Zobuchwepheshe Ezijwayelekile kanye Nezindlela Zokuhlola Zesisetshenziswa Sesistimu Ye-Electromechanical System".

3.11 Izinga lokuvikela lokuqashelwa kwepuleti lelayisense nokokusebenza kokuthwebula akufanele libe ngaphansi kwe-IP67.

4 Izisetshenziswa Zokubhekwa Kwevidiyo Izidingo Ezisebenzayo

Ikhamera ye-4.1 yokugada ividiyo kufanele ibe nomsebenzi wekhamera ye-infrared imini nobusuku, futhi kufanele ikwazi ukuthola indawo enesisindo esingami yomsebenzi wekhamera eyindilinga, futhi yonge okungengaphansi kwama-10s edatha yevidiyo eqoqwayo yobufakazi obugcwele kwezimoto ezithwala impahla ngokungemthetho.

4.2 Kufanele ibe nemisebenzi yokuzihlola, ukulinganisa indawo yokubuka kanye nesinxephezelo esizenzekelayo.

4.3 Izithombe zevidiyo ze-Forensic akufanele zibe ngaphansi kwamaphikseli ayizigidi ezi-3, futhi kufanele zicace futhi zizinze.

4.4 Kufanele ibe nomsebenzi wokuzungezisa nokusondeza, futhi ukuzungezisa okuvundlile nokuqondile kanye nokusondeza kwelensi kungenziwa ngokuvumelana nomyalo wokulawula.

4.5 Kufanele ibe nomsebenzi wokuhlanza nokukhipha amalambu enkungu emvula nesithwathwa, futhi kufanele ikwazi ukuhlanza, ukushisisa kanye nokuncibilikisa ikhava eyisivikelo ngesikhathi.

4.6 Izithombe zevidiyo ze-Forensic kufanele zidluliselwe ezingeni lesifunda (ledolobha) lokulawulwa kolwazi olugcwele kanye nenkundla yokuphoqelela okuqondile ngesikhathi sangempela.

4.7 Impahla yokuqapha ividiyo nezinye izinkomba zobuchwepheshe zezinsiza zayo zizohlangabezana nezinhlinzeko nezimfuneko ezifanele ze-GA/T995.

4.8 Ibanga elisebenzayo lokushisa kwendawo yokusebenza kufanele lifinyelele -20°C~+55°C, futhi izinkomba zobuchwepheshe zokumelana nokuswakama kwemvelo kufanele zihlangabezane nemithetho nezidingo ezifanele zemishini yangaphandle nemishini kagesi ye-JT/T817 "Izimfuneko Zobuchwepheshe Ezijwayelekile kanye Nezindlela Zokuhlola Zesisetshenziswa Sesistimu Ye-Electromechanical System".

5 Izidingo zokusebenza zemishini yokushicilela ulwazi

5.1 Kufanele ikwazi ukukhulula ulwazi lwesikhathi sangempela mayelana nokugcwala ngokweqile kwemoto kumshayeli wemoto engekho emthethweni elayisha kakhulu.

5.2 Kufanele ikwazi ukushicilela futhi ibonise ulwazi olunjengokushintshanisa umbhalo nokuskrola.

5.3 Izinkomba zokusebenza eziyinhloko nezinkomba zobuchwepheshe zezimpawu zolwazi eziguquguqukayo ze-LED zomgwaqo omkhulu zizohlangabezana nezinhlinzeko nezimfuneko ezifanele ze-GB/T23828 "Izimpawu Zolwazi Eziguquguqukayo ze-LED".

5.4 Ikholomu ekabili yohlobo lwe-gantry yomgwaqo onguthelawayeka we-LED yophawu olushintshashintshayo lwesikrini sokubonisa isikhala samaphikseli esivame ukusetshenziswa singakhethwa: 10mm, 16mm kanye no-25mm. Usayizi wendawo yokubonisa wemizila emine nemizila eyisithupha ingaba amamitha-skwele ayi-10 kanye namamitha-skwele ayi-14 ngokulandelana. Ifomethi yokuqukethwe eboniswayo ingaba umugqa ongu-1 namakholomu angu-14.

5.5 Isikhala samaphikseli sophawu lolwazi oluguquguqukayo lwekholomu eyodwa ye-LED singakhethwa: 10mm, 16mm kanye no-25mm. Ubukhulu besikrini sokubonisa bungakhethwa kusuka kumamitha-skwele ayi-6 kanye namamitha-skwele ayi-11. Ifomethi yokuqukethwe yesibonisi ingaba imigqa emi-4 namakholomu angu-9.

5.6 Idizayini nokusethwa kwezimpawu zolwazi oluguquguqukayo lwe-LED yomgwaqo onguthelawayeka kanye nebanga lokuqaphela okubonakalayo kufanele kucabangele ngokugcwele isivinini sangempela kanye nezidingo zokubonwa kokubukwayo zezimoto ezithwala impahla esigabeni somgwaqo, futhi kuhlangatshezwane nezinhlinzeko nezimfuneko ezifanele ze-GB/T23828 "Izimpawu Zolwazi Eziguquguqukayo ze-Highway LED".

6 Izidingo Zokusethwa Kwezimpawu Zethrafikhi

6.1 Setha uphawu lwethrafikhi ukuze ungene "endaweni yokukala neyokubona engami" ebangeni elingekho ngaphansi kwamamitha angu-200 phambi kwendawo yokuthola isisindo esingami.

6.2 Setha uphawu lwethrafikhi oluthi "akukho umzila ongashintshi" ongekho ngaphansi kwamamitha ayi-150 ngaphambi kwendawo yokuthola isisindo esingami.

6.3 Setha uphawu lwethrafikhi oluthi "Phakamisa ukuvinjelwa kokushintshwa komzila" ebangeni elingekho ngaphansi kwamamitha angu-200 ngemuva kwendawo yokuthola isisindo esingami.

6.4 Ukusethwa kwezimpawu zethrafikhi endaweni yokuthola isisindo esingami kuzothobelana nomklamo nezimfuneko ze-GB5768 "Izimpawu Nezimpawu Zethrafikhi Yomgwaqo".

7. Izidingo zemishini yokuphakelwa kwamandla kanye nesisekelo sokuvikela umbani

7.1 Uhlelo lokuqoqwa kolwazi olugcwele ngokweqile kanye nohlelo lwe-forensics luzohlonyiswa ngezintambo zikagesi ezizinzile nezithembekile, ezizokwazi ukuhlangabezana nezimfuneko zokusebenza okungaphazamiseki kokuphakelwa kukagesi amahora angama-24.

7.2 Izinyathelo ezidingekayo zokuvikela umbani kanye nokuvikela i-overvoltage kufanele zithathelwe isixhumi esibonakalayo sokuphakelwa kwamandla kanye nesixhumi esibonakalayo sokulawula ukuqoqwa kolwazi olugcwele kakhulu kanye nesistimu ye-forensics kanye nezingxenye ezihlobene, futhi izinyathelo zokuvikela zizohambisana nezinhlinzeko nezimfuneko ezifanele ze-JT/T817 "Izimfuneko Zobuchwepheshe Ezijwayelekile kanye Nezindlela Zokuhlola Zesisetshenziswa Sesistimu Kagesi Womgwaqo Omkhulu".

7.3 Uhlelo lokuqoqwa kolwazi olugcwele ngokweqile kanye nesistimu ye-forensics kufanele isebenzise indlela yokumisa eseduze enephuzu elilodwa, futhi kufanele kwamukelwe indlela ye-DC parallel grounding.

7.4 Ukuvikelwa kombani kanye nokumelana nogesi kokuqoqwa kolwazi olugcwele kakhulu kanye nemishini ye-forensics kuzoba ≤ 10 Ω, futhi ukumelana nokuvikela umhlabathi kuzoba ≤ 4 Ω.

8 Izidingo zokusebenza kwekhabhinethi yokulawula insimu

8.1 Ikhabhinethi yokulawula endaweni emiswe ngokuqoqwa kolwazi olugcwele ngokweqile kanye nohlelo lwe-forensics kufanele ikwazi ukugcina amaphrosesa wokutholwa kwedatha, izithungatha zezimoto, amaswishi enethiwekhi nezinye izinto zokusebenza. Kufanele ikwazi ukulayisha ulwazi lomthwalo weloli ku-Provincial Department of Transportation Information Center Traffic Comprehensive Administrative Direct Enforcement Platform, futhi ikwazi ukudlulisa ulwazi lomthwalo weloli kuphawu lolwazi oluguquguqukayo lwe-LED lomgwaqo onguthelawayeka ngesikhathi sangempela ukuze likhishwe futhi liboniswe.

8.2 Ikhabhinethi yokulawula izoklanywa nge-double layer chassis seal, engavimbela ngempumelelo uthuli nemvula, futhi ibe nohlelo oluzimele lokulawula izinga lokushisa.

8.3 Ikhabhinethi yokulawula kufanele yakhelwe ngezikhala ukuze kube lula ukunwetshwa komsebenzi.

8.4 Ikhabhinethi yokulawula kufanele ifakwe okokusebenza kokuvikela ukuphepha kwedatha ukugwema ukuvuza kwedatha yokuthola okungaphezu komkhawulo.

9. Izidingo zokusetha izindawo zokukala ezingami zokugcwala komgwaqo omkhulu

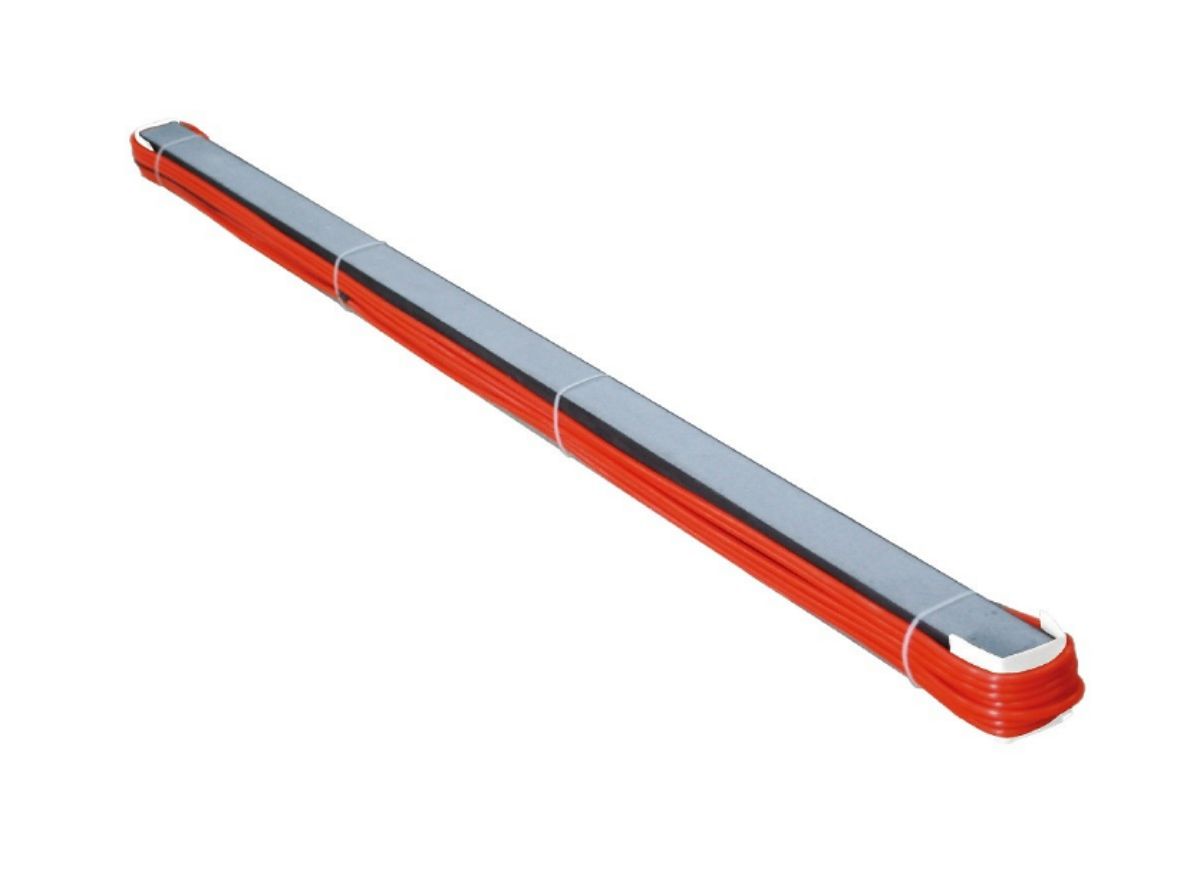

I-9.1 Indawo yokuthola isisindo esingayeki ihlanganisa umthwali wemishini yokukala engayeki (i-quartz crystal sensor) kanye nezigaba zayo zomhlahlandlela ngaphambili nangemuva (ngokuvumelana nomgwaqo oqinile wamamitha angu-30 ngaphambili namamitha angu-15 ngemuva) (Umfanekiso 2-1).

Umfanekiso 2-1 Umdwebo wohlelo wendawo yesisindo esingami

10 Izindlela, izidingo ezithile zimi kanje:

(1) I-radius ejikayo yomugqa omaphakathi womgwaqo wesigaba somhlahlandlela wama-60m kanye nesigaba somgwaqo esingemuva esingama-30m endaweni etholwayo enesisindo esingami kufanele sibe ≥ 1.7km.

(2) Ithambeka lelongitudinal lendawo yomgwaqo engxenyeni engaphambili engu-60m yomhlahlandlela kanye nengxenye yomgwaqo engemuva engu-30m endaweni yokuthola isisindo esingami kufanele ibe ≤2%.

(3) Inani le-slope eliphambanayo elihamba ngezinyawo le-i lengxenye yomgwaqo engu-60m engaphambili kanye nengxenye yomgwaqo engu-30m engemuva yendawo yokuthola isisindo esingami kufanele ihlangabezane no-1% ≤ i ≤2%.

(4) Akufanele kube nezithiyo ezivimba umzila womshayeli lapho abona khona ngaphakathi kwesigaba somgwaqo esingu-150m ngaphambi kwendawo yokuthola isisindo esingami.

(5) Ibanga phakathi kwendawo yendawo yesisindo neyokuthola okungami kanye nendawo yokungena nokuphuma emhubheni onguthelawayeka endaweni efanayo yomgwaqo akumele ibe ngaphansi kuka-2km futhi akumele ibe ngaphansi kwe-1km.

(6) Iphutha elivundlile lokuxhumana phakathi kwenzwa nendawo yomgwaqo alikho ngaphezu kuka-0.1mm

9.3 Ukuze kuqinisekiswe ukunemba kwedatha yesisindo esingami kanye nokuphepha kokushayela, ukuhlukaniswa komzila womgwaqo wengxenye yomgwaqo engu-60m engaphambili kanye nengxenye yomgwaqo engumhlahlandlela oyi-30m yangemuva yendawo yokuthola isisindo esingami kufanele ihlukaniswe ngentambo eqinile.

9.4 Indawo yokukala neyokuhlola engami ukuze iqondise ukwakhiwa kwezingxenye zomgwaqo

(1) Umbhede womgwaqo wengxenye yomgwaqo oyinkomba kufanele uzinze, futhi i-coefficient yokushayisana yendawo egandayiwe kufanele ihlangabezane nezidingo zomklamo wesigaba somgwaqo.

(2) Indawo egandayiwe yengxenye yomgwaqo oyinkomba kufanele ibe bushelelezi futhi iminyene, futhi indawo egandaywe ngetiyela akufanele ibe namarula, imigodi, indawo engaphansi, ukuminyana, imifantu, imifantu yenethiwekhi, namaqhuqhuva, futhi indawo egandaywe ngosimende akufanele inyakaze, amapuleti aphukile, indawo ephansi, ukunqwabelana kodaka nezinye izifo. Ukuma kwendawo egandaywe ngosimende kanye nendawo egandaywe ngokhonkolo yetiyela kuzohlangabezana nezinhlinzeko nezimfuneko ezifanele ze-JTGF80-1 "Amazinga Okuhlola Ikhwalithi Yobunjiniyela Bomgwaqo Omkhulu kanye Namazinga Okuhlola".

(3) Ububanzi bomgwaqo wengxenye yomgwaqo oyinkomba kufanele bukwazi ukusekela indlela evamile yemoto ethwala impahla ebanzi kunazo zonke phakathi kwebanga lokukala.

(4) Ulayini ophakathi nendawo ogandaywayo endaweni yesisindo nokuhlola okungami kufanele uhlukaniswe ngemigqa eqinile ephuzi (owodwa ophuzi) owodwa, futhi umugqa wokuhlukanisa umzila kufanele uhlukaniswe ngemigqa eqinile emhlophe.

3. I-interface protocol nezidingo zefomethi yedatha

Iphrothokholi yesixhumi esibonakalayo nefomethi yedatha yesistimu yokutholwa komgwaqo onguthelawayeka ongayeki kufanele ihlangabezane nezinhlinzeko nezimfuneko "ze-Fujian Traffic Comprehensive Administrative Direct Enforcement Engineering Design Plan" ukuze kuqinisekiswe ukuxhumana kanye nokwabelana ngolwazi phakathi kwesifunda (isifunda), ukuphathwa kolwazi lokulayishwa ngokweqile kukamasipala nesifundazwe (okuhlanganisa nokuphoqelela okuqondile) izinkundla.

Inkampani engu-Enviko Technology Co., Ltd

E-mail: info@enviko-tech.com

https://www.envikotech.com

Ihhovisi laseChengdu: No. 2004, Unit 1, Building 2, No. 158, Tianfu 4th Street, Hi-tech Zone, Chengdu

Ihhovisi laseHong Kong: 8F, Cheung Wang Building, 251 San Wui Street, Hong Kong

Ifekthri: Isakhiwo 36, Indawo Yezimboni yaseJinjialin, Idolobha laseMianyang, Isifundazwe saseSichuan

Isikhathi sokuthumela: Jan-25-2024