I-Piezoelectric Quartz Dynamic Weighing Sensor CET8312

Incazelo emfushane:

I-CET8312 I-Piezoelectric Quartz Dynamic Weighing Sensor inezici zebanga lokulinganisa elibanzi, ukuzinza okuhle kwesikhathi eside, ukuphindaphinda okuhle, ukunemba okuphezulu kokulinganisa kanye nemvamisa yokuphendula okuphezulu, ngakho ifaneleka ngokukhethekile ukutholwa kwesisindo esiguqukayo. Kuyinzwa yesisindo esiqinile, eshukumisayo esekelwe kumgomo we-piezoelectric kanye nesakhiwo esinelungelo lobunikazi. Yakhiwe nge-piezoelectric quartz crystal sheet, ipuleti le-electrode kanye nedivaysi ekhethekile yokuthwala ugongolo. Ihlukaniswe imitha engu-1, 1.5-imitha, 1.75-imitha, 2-imitha yosayizi imininingwane, ingahlanganiswa ibe izilinganiso ezihlukahlukene zezinzwa zethrafikhi yomgwaqo, ingakwazi ukuzivumelanisa nezidingo zesisindo ezinamandla zomgwaqo.

Imininingwane Yomkhiqizo

Imingcele Yezobuchwepheshe

| Ubukhulu besigaba esiphambanayo | (48mm+58mm)*58mm | ||

| Ubude | 1m, 1.5m, 1.75m, 2m | ||

| Ibanga lesisindo samasondo | 0.05T~40T | ||

| Umthamo wokulayisha ngokweqile | 150% FS | ||

| Ukuzwela komthwalo | 2±5%pC/N | ||

| Ibanga lesivinini | (0.5-200) km/h | ||

| Ibanga lokuvikela | IP68 | Ukuphazamiseka kokuphumayo | >1010Ω |

| Izinga lokushisa lokusebenza. | -45℃80℃ | Okukhiphayo izinga lokushisa | <0.04%FS/ ℃ |

| Ukuxhunywa kukagesi | Ikhebula le-coaxial lomsindo we-frequency ephezulu | ||

| Bearing surface | I-Bearing surface ingapholishwa | ||

| Okungaqondile | ≤±2% FS (ukunemba kokulinganisa okumile kwezinzwa endaweni ngayinye) | ||

| Ukuvumelana | ≤± 4% FS (ukunemba kokulinganisa okumile kwamaphoyinti wokuma ahlukene wenzwa) | ||

| Ukuphindaphinda | ≤±2% FS (ukunemba kokulinganisa okumile kwezinzwa endaweni efanayo) | ||

| Iphutha lokunemba elihlanganisiwe | ≤±5% | ||

Indlela Yokufaka

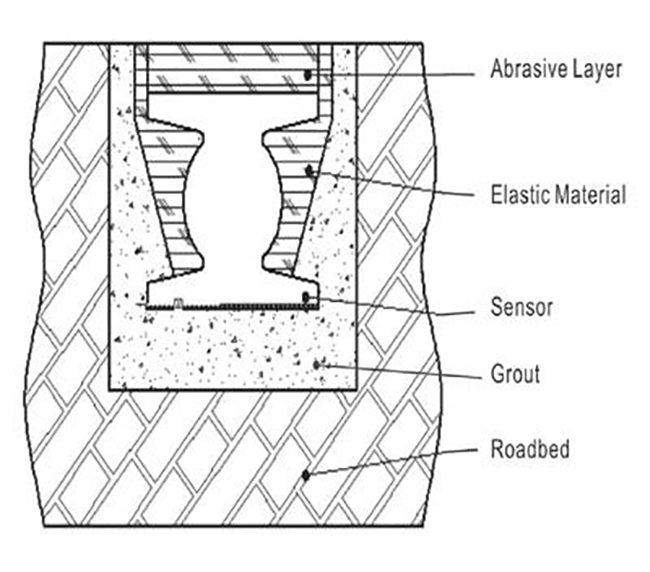

Isakhiwo Sisonke

Ukuze uqinisekise umphumela wokuhlola wakho konke ukufakwa kwenzwa, ukukhethwa kwesayithi kufanele kuqine. Kuphakanyiswa ukuthi umgwaqo ogandayiwe usimende oqinile kufanele ukhethwe njengesisekelo sokufakwa kwezinzwa, futhi umgwaqo oguquguqukayo njengetiyela kufanele ushintshwe. Uma kungenjalo, ukunemba kokulinganisa noma impilo yesevisi yenzwa ingase ithinteke.

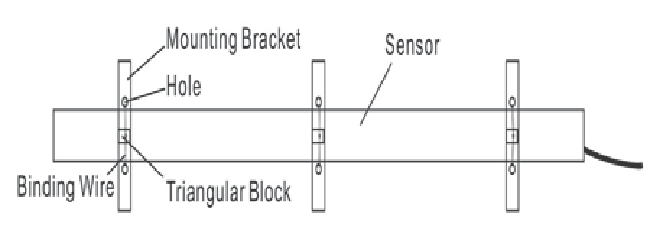

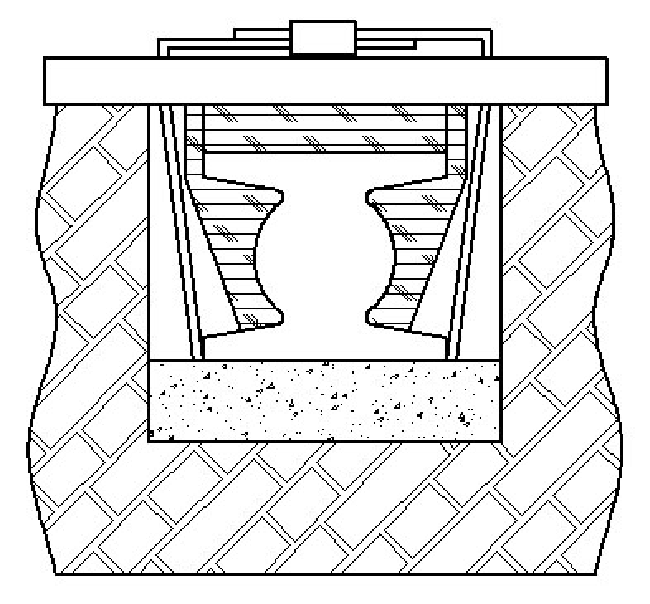

Ubakaki Wokukhweza

Ngemuva kokuthi indawo isinqunyiwe, ubakaki okhuphukayo onezimbobo ezinikezwe izinzwa kufanele ulungiswe inzwa nge-tape tie-wire ende, bese uhlamvu oluncane lukanxantathu lusetshenziselwa ukuxhuma igebe phakathi kwebhande lokubopha kanye nebakaki elifakayo, ukuze liqiniswe. Uma abasebenzi banele, isinyathelo (2) kanye (3) singenziwa kanyekanye. Njengoba kuboniswe ngenhla.

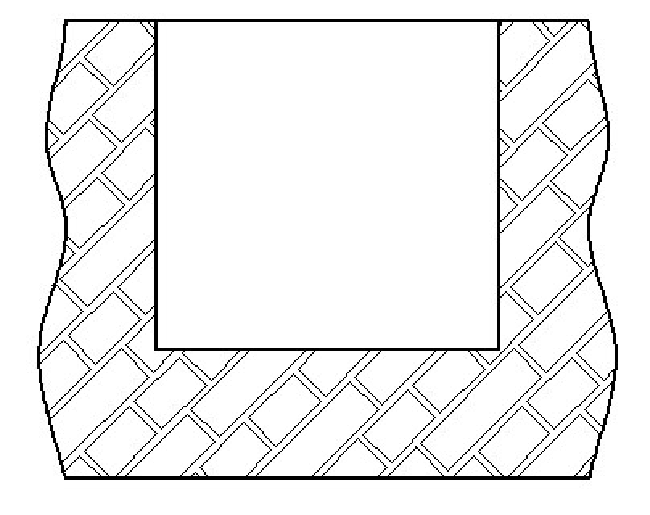

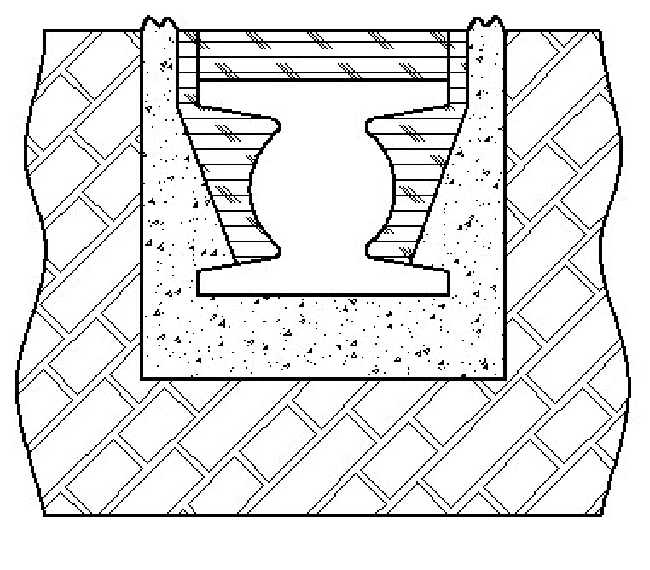

I-Pavement Grooving

Sebenzisa irula noma elinye ithuluzi ukuze unqume indawo yokukhweza yenzwa yesisindo esiguqukayo. Umshini wokusika usetshenziselwa ukuvula ama-grooves angama-rectangular emgwaqeni.

Uma ama-grooves engalingani futhi enama-bumps amancane emaphethelweni emigodi, ububanzi be-grooves buyi-20 mm ngaphezu kwenzwa, ukujula kwe-grooves ku-20 mm ngaphezu kwe-sensor, no-50 mm ubude kunalowo wenzwa. I-Cable groove iyi-10 mm ububanzi, 50 mm ukushona;

Uma ama-grooves enziwe ngokucophelela futhi emaphethelweni emigodi abushelelezi, ububanzi be-grooves buyi-5-10mm ngaphezu kwezinzwa, ukujula kwama-grooves ku-5-10mm ngaphezu kwalokho kwezinzwa, futhi ubude bemigqa buyi-20-50mm ngaphezu kwezinzwa. Igroove yekhebula ingu-10 mm ububanzi, 50 mm ukushona.

Iphansi lizosikwa, i-silt namanzi emigodini izoshaywa ihlanzekile ngepompo yomoya (ukuze yomiswe kahle ukuze igcwalise i-grout), futhi indawo engaphezulu yezinhlangothi zombili ze-grooves izoxhunywa nge-tape.

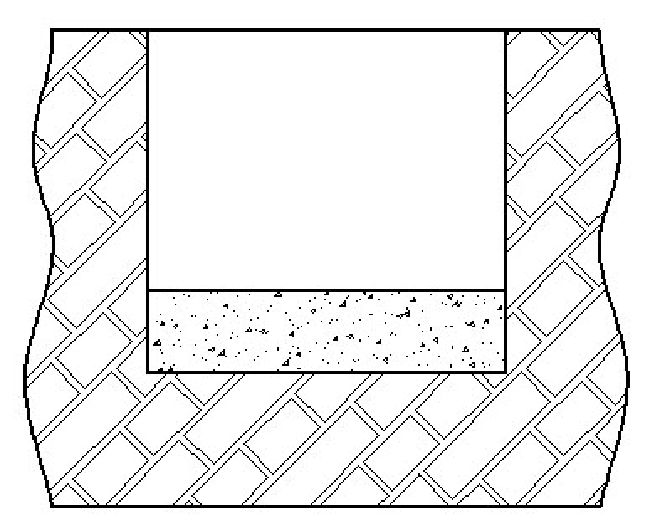

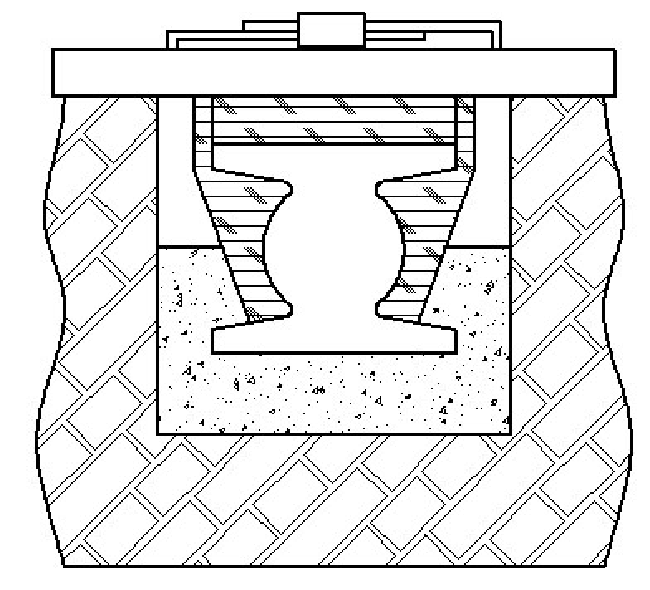

Okokuqala Grouting

Vula i-grout yokufaka, ngokwesilinganiso esinqunyiwe ukuze ulungise i-grout exutshwe, uxube ngokushesha i-grout ngamathuluzi, bese uthele ngokulinganayo eceleni kwendlela yobude be-groove, ukugcwaliswa kokuqala emgodini kufanele kube ngaphansi kwe-1/3 yokujula kwe-groove.

Ukubekwa Kwenzwa

Beka ngobumnene inzwa enobakaki okhwezwayo endaweni egcwele i-grout, lungisa ubakaki okhwezwayo futhi wenze i-fulcrum ngayinye ithinte indawo engaphezulu yesikhala, futhi uqinisekise ukuthi inzwa iphakathi nendawo. Uma izinzwa ezimbili noma ngaphezulu zifakwe ku-slot efanayo, ukunakwa okukhethekile kufanele kukhokhwe engxenyeni yokuxhuma.

Ubuso obungaphezulu bezinzwa ezimbili kufanele bube sezingeni elifanayo elivundlile, futhi ukuhlangana kuzoba kuncane ngangokunokwenzeka, ngaphandle kwalokho iphutha lokulinganisa lizobangelwa. Yonga isikhathi esiningi ngangokunokwenzeka esinyathelweni (4) kanye (5), noma i-grout izophulukisa (amahora angu-1-2 wesikhathi esivamile sokuphulukisa seglue yethu).

Ukususwa Kwebakaki Enyukayo kanye Ne-Grouting Yesibili

Ngemuva kokuthi i-grout ilashwe ngokuyisisekelo, bheka umphumela wokuqala wokufakwa kwenzwa, futhi uyilungise ngesikhathi esifanele uma kunesidingo. Konke sekumi ngomumo, bese ukhipha ubakaki, uqhubeke ne-grouting yesibili. Lo mjovo ukhawulelwe kubude obungaphezulu benzwa.

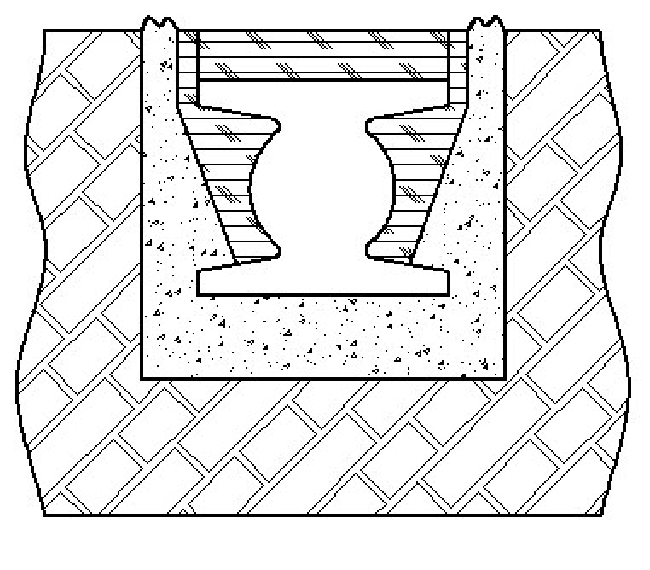

I-Grouting Yesithathu

Phakathi nesikhathi sokuphulukisa, qaphela ukwandisa inani le-grout nganoma yisiphi isikhathi, ukuze izinga eliphelele le-grout ngemva kokugcwalisa liphakeme kancane kunomgwaqo.

Ukugaya Okungaphezulu

Ngemuva kokuthi yonke i-grout yokufaka isifinyelele amandla okuphulukisa, krazula itheyiphu, futhi ugaye indawo ye-groove nendawo yomgwaqo, yenza ukuhlolwa kokulayisha kuqala ngemoto evamile noma ezinye izimoto ukuze uhlole ukuthi ukufakwa kwenzwa kulungile yini.

Uma ukuhlolwa kokulayisha kuqala kujwayelekile, ukufakwa kuyinto

kuqediwe.

Izaziso Zokufaka

5.1Kunqatshelwe ngokuphelele ukusebenzisa inzwa ngaphezu kobubanzi nezinga lokushisa lokusebenza isikhathi eside.

I-5.2 Akuvunyelwe ngokuqinile ukukala ukumelana nokufakwa kwenzwa ngemitha yokumelana ephezulu ngaphezu kwe-1000V.

5.3 Abasebenzi abangebona abaqeqeshiwe banqatshelwe ngokuphelele ukuyiqinisekisa.

5.4Indlela yokulinganisa kufanele ihambisane nezinto ze-aluminium, ngaphandle kwalokho kudingeka imiyalelo ekhethekile lapho u-oda.

5.5Ukuphela kokuphumayo kwenzwa L5/Q9 kufanele kugcinwe komile futhi kuhlanzekile ngesikhathi sokulinganisa, ngaphandle kwalokho okukhiphayo kwesignali akuzinzile.

5.6 Indawo yokucindezela yenzwa ngeke ishaywe ngensimbi ebuthuntu noma ngamandla amakhulu.

5.7 I-bandwidth ye-amplifier yokushaja izoba phezulu kunaleyo yenzwa, ngaphandle kwalapho kungekho sidingo esikhethekile sokuphendula imvamisa.

5.8 Ukufakwa kwezinzwa kufanele kwenziwe ngokuhambisana ngokuqinile nezidingo ezifanele zemiyalelo ukuze kufinyelelwe isilinganiso esinembile.

5.9 Uma kukhona ukuphazamiseka okunamandla kazibuthe eduze nesilinganiso, kufanele kuthathwe izinyathelo ezithile zokuvikela.

5.10Ikhebuli yenzwa kanye nesikhulisi seshaja kufanele sisebenzise intambo ye-coaxial enomsindo we-high frequency static.

Okunamathiselwe

Imanuwali 1 PCS

Ukufaneleka kokuqinisekiswa 1 PCS Isitifiketi 1 PCS

I-Hangtag 1 PCS

Ikhebula lokukhiphayo le-Q9 1 PCS

U-Enviko ubesebenza ku-Weigh-in-Motion Systems iminyaka engaphezu kwe-10. Izinzwa zethu ze-WIM neminye imikhiqizo yaziwa kabanzi embonini ye-ITS.